1. SCM Objectives:

To begin, SCM’s goals are to reach or surpass the required or desired level of customer service in specific markets/segments, as well as to optimise total supply chain investment and cost. Supply chain management has long recognised this service/cost strategy as crucial. This strategy necessitates that businesses have a thorough awareness of both concerns. The marketplace dictates customer service expectations, which “sets the spec” for the supply chain. To achieve this level of service at the lowest possible cost, the supply chain’s “Non Value Adding activities” (NVAs) must be eliminated.

2. SCM Philosophy

Second, each product or service is supplied to the final consumer (the only source of “real” money in the chain) via a series of frequently complex moves among the enterprises that make up the entire chain. Inefficiencies in any part of the network will prevent the chain from reaching its full competitive potential. To put it another way, rather than corporations merely competing with other companies, supply chains are increasingly competing with other supply chains. The term “supply chain” refers to how the chain is only as strong as its weakest link.

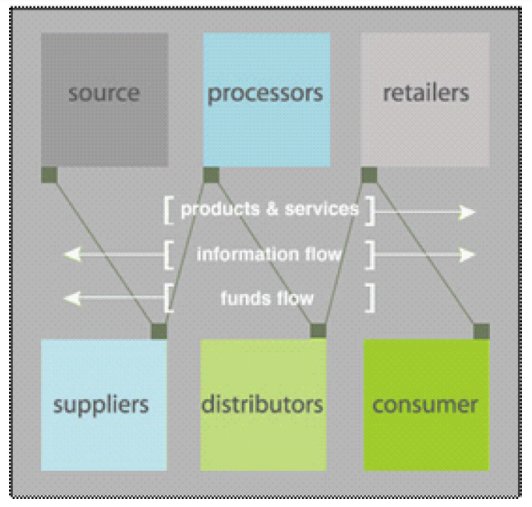

A “macro” supply chain is depicted in Figure 1 (below), with materials moving from the raw material source through the various phases of the chain to the final customer. The money then circulates back up the system. The point is that each link is important, and that value is produced and profit is generated at each one.

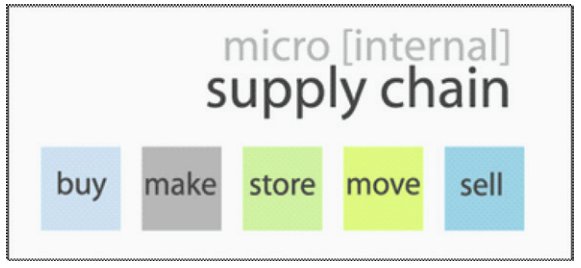

Most businesses can be described in terms of the five functions: buy; make; store; move; and, sell. This is known as the “micro” or internal supply chain as shown in Figure 2.

Traditionally, these functions have been controlled separately, often at odds with one another. SCM entails thinking outside of the box, strengthening inter-functional connections, and creating ways for them to work together. Recognising that the whole is greater than the sum of its parts necessitates better integration between purchasing and procurement (buy), production planning and control (make), warehouse management (store), transportation management (move), and customer relationship management (sell).

3. Managing the Flows

Material flows, money flows, and information flows across the supply chain must be managed in an integrated and holistic manner, driven by overall service and cost objectives, for a supply chain to achieve optimum effectiveness and efficiency. The image of a macro chain presented in Figure 1 (above) depicts the flow of materials, money (funds), and information amongst the enterprises that make up the chain. The functions that make up the micro chain can be treated in the same way. The most crucial of these operations, it may be claimed, is managing information flows. This is because the flow or movement of things or money is almost always accompanied by a flow of knowledge. As a result, efficient management of material and financial flows is contingent on good management of corresponding information flows. As a result, information and communication technology (ICT) is quickly becoming a key SCM enabler.

4. Supply Chain Relationship

Finally, this comprehensive approach necessitates a rethinking of how internal and external customer/supplier relationships are formed and managed. SCM isn’t a “zero-sum” game with antagonistic relationships. Rather, it must be a “win-win” game built on collaborative efforts. This concept applies to interactions between the major “internal” supply chain operations of buy, make, store, move, and sell, as well as relationships between an organization’s external customers and suppliers. In recent years, one of the most visible manifestations of supply chain philosophy has been the shift away from antagonistic relationships with key external suppliers toward relationships built on mutual trust and benefits, openness, and shared aims and objectives.