Sedimentation

Sedimentation is a water treatment procedure in which there is little or no movement in the water and suspended materials descend to the bottom under the force of gravity and form sediment.

Settling’s Purpose:

- To get rid of the coarsely distributed phase.

- To eliminate contaminants that have coagulated and flocculated.

- To eliminate contaminants that have been collected after chemical treatment.

- After the activated sludge process/fooling filters, settle the sludge (biomass).

Settling Principles:

- When turbulence is reduced by providing storage, suspended particles in water with a specific gravity greater than water tend to settle down by gravity.

- A settling tank is a basin in which the flow is slowed.

- The detention period is the theoretical average time for which the water is held in the settling tank.

Types of Settling:

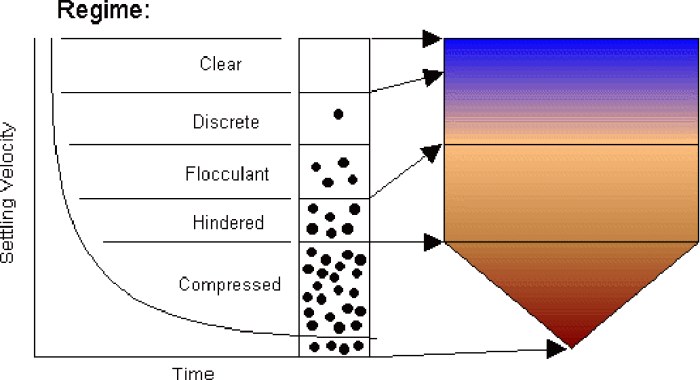

Type I: Discrete particle settling

Particles settle one at a time, without interacting with one another.

Type II: Flocculent Particles

Flocculation increases the bulk of the particles, causing them to settle more quickly.

Type III: Zone or hindered settling

Individual particles tend to retain in fixed positions with regard to one another while the mass of the particles settles as a unit.

Type IV: compression

Because the particle concentration is so high, sedimentation can only happen if the structure is compacted.

Sedimentation Types:

Plain sedimentation refers to the process of causing suspended materials to settle by gravity under still water conditions.

- Plain sedimentation: This is the process of sediments and contaminants in raw water settling to the bottom of a sedimentation basin using only gravity and no chemicals. This technology is very inexpensive, and it is commonly employed in all water filtration and purification systems.

- Sedimentation with coagulation: In this procedure, chemicals are combined in water, which is then cycled by pumps for two hours each day, settling suspended solids in the bottom of the reservoir or tank.

Zones of Sedimentation Basins:

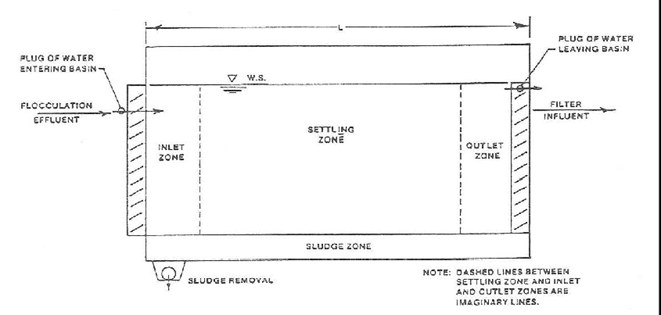

The following zones are found in most sedimentation tanks:

Zone of the Inlet

The inlet or influent zone should evenly distribute flow throughout the tank’s intake. Baffles are used in the standard design to gently disperse the flow throughout the tank’s entire entrance and prevent short-circuiting. (A condition in which a portion of the influent water departs the tank too soon by flowing across the top or along the bottom is referred to as short-circuiting.) Sometimes the baffle is constructed as a wall across the intake, with holes perforated across the tank’s breadth.

Zone of Settlement

The sedimentation basin’s settling zone is the greatest part. This zone offers the stillness that the suspended particles require to settle.

Zone of Sludge

The sludge zone, positioned at the tank’s bottom, serves as a holding area for the sludge before it is taken for further treatment or disposal. Inlets in basins should be built to reduce high flow velocities towards the tank’s bottom. Sludge could be swept up and out of the tank if high flow velocities are allowed to enter the sludge zone. Scraper or vacuum devices that move along the bottom remove sludge from the sludge zone for further treatment.

Zone of Outlets

The basin exit zone (also known as the launder) should enable a seamless transition from the sedimentation zone to the tank’s outlet. The depth of water in the basin is likewise controlled by this region of the tank. The overflow rate is controlled by weirs at the tank’s end, which prevent sediments from rising to the weirs and leaving the tank before they settle out. The weir length in the tank must be sufficient to manage the overflow rate, which should not exceed 20,000 gallons per day per foot of weir.

Types of Settling Tanks:

1. Fill and draw

The intermittent tanks also called quiescent type tanks are those which store water for a certain period and keep it in complete rest.

2. Continuous flow type

In a continuous flow type tank, the flow velocity is only reduced and the water is not brought to complete rest as is done in an intermittent type.

3. Rectangular

The most basic design is a rectangular basin, which allows water to flow horizontally through a long tank. Large-scale water treatment plants frequently use this sort of basin.

4. Circular

Clarifiers are circular sedimentation basins that have horizontal flow. The functional zones of circular settling basins are the same as those of long rectangular basins, but the flow regime is different. The horizontal velocity of the water decreases as the distance from the centre grows when the flow enters at the centre and is confounded to flow radially towards the periphery. In contrast to the straight line journey in the long rectangular tank, the particle travel in a circular basin is a parabola.