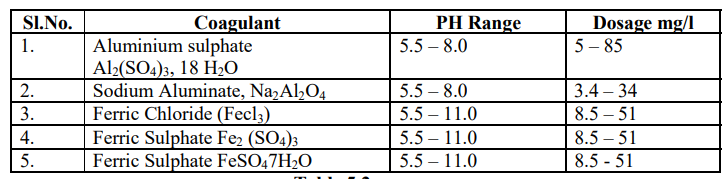

Fine clay and colloidal particles that are electrically charged are continuously in motion and never settle down in water that contains these substances. To remove these contaminants that are not naturally present in the water, several chemicals are added plain sedimentation eliminated by. The chemical form is gelatinous, soluble, and flocculent Very small suspended particles and colloidal contaminants are captured and absorbed by precipitate when it was forming and making its way through water. Additionally, these coagulants have the benefit of getting rid of the water’s colour, flavour, and smell the murkiness of water decreased by 5–10 ppm, and bacteria can eliminate up to 65% of it. The following are the mostly used Coagulants with normal dose and PH values required for best floc formation as shown in Table.

Coagulants are selected based on the PH of the water. Because it is inexpensive and simple to store as solid crystals for extended periods of time, alum, or aluminium sulphate, is commonly employed in all treatment plants.

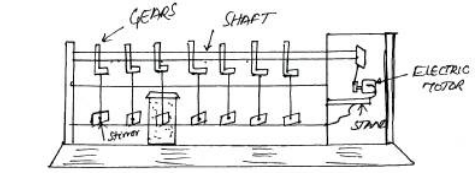

The amount of coagulants that should be added to the water varies on the type of coagulant, the turbidity, colour, PH, temperature, and mixing and flocculation times of the water. A Jar test, as seen in Fig, is used to establish the ideal coagulant dose needed for a water treatment facility.

To begin the experiment, a sample of water is first taken in each jar, and then varied doses of coagulant are added. Each jar’s addition of coagulant is reported along with its quantity. The paddles are then all revolved for around 10 minutes at a speed of 30 to 40 RPM with the assistance of an electric motor. Following that, the speed is slowed down and the paddles are rotated for 20 to 30 minutes. The paddles are stopped from rotating, and the floc that has formed in each Jar is documented and allowed to settle. The ideal dose of coagulants is the one that produces the best floc.

It is possible to feed or enable the entry of the coagulants either in powder form (dry feeding) or in solution form (wet feeding). The following techniques are used to combine the coagulant and water to create the floc.

- Centrifugal pump

- Compressed air

- Hydraulic jump

- Mixing channel

- Mixing basins with buffle walls

- Mixing basins with mechanical means