What is structural cracks?

A crack is a complete or incomplete separation of concrete into two or more parts produced by breaking or fracturing.

Reason for cracks in structures:

1. Initial Shrinkage:

Building materials shrink in the beginning. This is a partially irretrievable shrinkage. Shrinkage cracks in structures can be reduced by using less rich cement mortar in the masonry and by application of plastering on brickwork. Shrinkage cracks in plastering can be minimized by using less rich motor and provides resistance to durability.

2. Thermal Movement:

Building materials undergo expansion and compression. Thermal movement creates cracks leading shear stresses. Thermal movement are strongest, demand attention. Daily changes have a more damaging effect than the seasonal changes, which are regular. On the other hand, in seasonal changes, the pressure gets relieved to a large extent on account of creep.

3. Elastic Deformation:

Unevenly loaded walls undergo large extent stress development, leading to cracks in structure. Building material with different elastic property develop different shear stress resulting to cracks at the junctions. Elastic deformations are caused depending on loading. Extent of deformation is based on the elastic property of the building material.

4. Creep Movement:

Gradual and slow time-dependent distortion of the concrete structure under constant loads is known as creep. It leads to development of great amount of stress ultimately developing cracks in structures. Creep also is the reason for the increase in cement and water content. the increase of temperature in the steel bars surges creep as well.

5. Chemical Reaction:

Internal stress and chemical reaction are directly proportional, and leads to increase in overall volume. Chemical reactions lead to weakening of building material. Carbonation in cement-based materials, sulphate attack on cement products, alkali-aggregate reaction, and corrosion of reinforcement in concrete are few of the most common types of chemical actions on building materials.

6. Foundation Movement and Settlement of Soil:

Differential settlement in the foundation causes shear crack. Expansive soils which are vulnerable to swelling on absorbing moisture and shrink on drying due to change in moisture content of the soil are highly prone to cracking in structure.

7. Cracking Due To Vegetation:

The presence of any vegetation leads to formation cracks in the walls of a building. Major reason for this is expansive action of roots growing in gaps of brick masonry or in foundation. The cracks occur in clay soil due to moisture contained by roots. Growth of roots develops tension and also cause cracks.

8. Permeability Of Concrete:

Depletion of concrete begins with movement of aggressive substance. Depletion is many caused by weathering action, chemical attack, or any other process of deterioration. Several factors which control concrete permeability, water-cement ratio, curing, air voids due to deficient compaction, use of admixtures, micro-cracks due to loading, cyclic exposure to thermal differences, and oldness of the concrete.

9. Structural Design:

For any structure to have good performance it is very important to consider all the environmental features including soil investigation, which helps the deisigner to comeup with best and funtional structural design.

10. Poor Workmanship:

Skilled labour and good structure goes hand in hand. Inferior mixing of construction materials, like sand, cement, and aggregate cause cracks on the walls, slabs, beams, etc. All of these lead to development of cracks in structure.

11. Poor (Or) Lack Of Maintenance:

Performance of any structure depends on the care taken. Regular maintenance would reduce the chance of cracks in any structure.

12. Natural Forces:

flooding’s, Earthquakes, tremors, winds, rains and many others can cause cracks in the buildings.

Types of cracks in structures:

We can majorly see two types of cracks in any structure,

- Non-Structural Cracks

- Structural Cracks

Non-Structural Cracks:

The stresses induced internally in any building material lead to non Structural cracks. These cracks do not cause major default in the structure but aesthetically is not pleasing.

Structural Cracks:

Incorrect design, faulty construction or overloading affect the structure and cause weakening. These cracks cause major problems in the structure.

There are many types of structural cracks, Here are 7 types of cracks and their prevention:

1. Plastic shrinkage cracks:

Loss of moisture quickly in slabs or structural member forms these cracks. concrete in plastic state it is full of water with time water evaporates leaving voids, these voids or spaces decrease the strength of concrete. These cracks are very fine and barely visible. That plastic shrinkage cracks don’t just exist on the surface, they extend throughout the entire thickness of the slab.

Measures to prevent plastic shrinkage in structure:

- By providing Control joints.

- By use of plastic sheeting to cover the surface between finishing operations.

- Choose Water ratio according the Is code or according the temperature.

2. Crazing & Crusting Cracks:

Crazing :

The top of a concrete slab loses moisture too quickly, this leads cracking. These cracks are rarely more than 3 mm deep. These are very fine, surface cracks that resemble spider webs or shattered glass. These are random cracks on surface.

Crusting :

During stamped concrete finishes, surface crusting is one of the most difficult problems to manage in the field. This leads to formation of larege number of cracks on the surface and is not aesthetically pleasing. On windy days where the top of the slab dries out quicker than the bottom, the top of the concrete surface can become crusty. This can be reduced by using admixtures increase the setting time.

3. Settling cracks:

The cracks formed due to the settling of structure. The major reason for such cracks are, improper compaction of soil. These are the very dangerous cracks.

4. Expansion cracks:

Another reason that concrete cracks is expansion. In summer a concrete slab is more likely to expand as it gets hotter. This produces great stress in slab. As the concrete expands, it pushes the adjacent objects, such as a brick wall or an adjacent slab of concrete, the resulting force will cause something to crack. An expansion joint is a point of separation, or isolation joint, between two static surfaces.

5. Heaving cracks:

Heaving is caused by clay soils expansion by absorbing moisture. The amount of water in the ground is often uneven and so the movement in the house is uneven. Cracking is ground movement is also brought on by freeze/thaw cycles. The presence of large tree roots can also cause concrete to heave; the growing roots of these trees can lift and crack the concrete.

6. Overloading cracks:

Concrete is weak in tension. Excessive amounts of load on top of a concrete can cause cracking. If distribution of loads is not done properly develops these cracks.

7. Corrosion of Reinforcement:

As the steel corrodes, the resulting rust occupies a greater volume than the steel. This expansion creates tensile stresses in the concrete, which can eventually cause cracking, delamination, and spalling.

Methods of crack repair in structures

1. Epoxy injection:

Epoxy injection is an method of repairing non-moving cracks in concrete walls, slabs, columns. Here it requires the establishment of entry and venting ports along the cracks, sealing the crack on exposed surfaces, and injecting the epoxy under pressure.

2. Routing and sealing:

The cracks are made wider at the surface and then the groove is filled with flexible sealant. This is a common and simple technique for crack treatment. It can be done on vertical surfaces and curved surface.

3. Stitching:

It is a permanent structural repairs solution for masonry and cracked wall reinforcement. It is done by drilling holes on both sides of the crack, cleaning the holes and anchoring the legs of the staples in the holes with a non-shrink grout.

4. Drilling and plugging:

It is only applicable when cracks run in straight lines and are accessible. This method is used to treat vertical cracks in retaining walls.

5. Gravity Filling:

Low viscosity monomers and resins are used to seal cracks with surface widths of 0.001 to 0.08 inch. High molecular weight methacrylates, urethanes, and some low viscosity epoxies are used successfully.

6. Dry packing:

It is the hand placement of a low water content mortar followed by tamping or ramming of the mortar into place and also helps in producing contact between the mortar and the existing concrete.

7. Polymer impregnation:

Monomer systems is used for repair of some cracks. A monomer system is a liquid consisting of monomers which will polymerize into a solid. The most common monomer used for this purpose is methyl methacrylate.

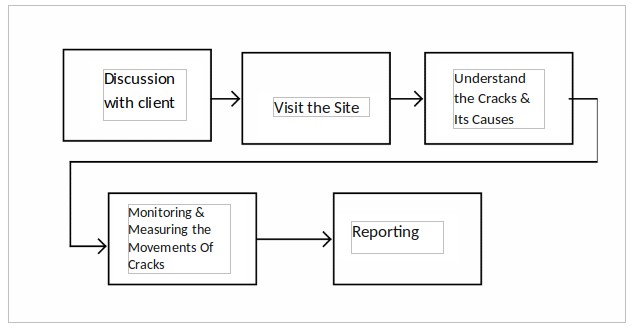

Principles of investigation of cracks

STEP 1: Discussion with the Client of the building

One of the most important things is to discuss with client or owner about cracks, ask them:

- When was the building constructed ? Date and year of construction?

- Ask for building drawings ? (And the details of constructions if avaliable)

- Ask them when the cracks first appeared? Or how long was the cracks seen?

- Check whether the client makes complaints about pieces of concrete falling, excessive deflections, large cracks, staining, or water leakages?

- Ask them whether any repair work was carried out if yes, what was the result?

STEP 2: Visit the Site

- When you visit the site, always carry building drawings. Check whether the building is constructed as per the plan.

- Check its present use of the structure or any change in the usage of building.

- Photograph the cracks and number them

- Mark the width of crack

- Check for any tilting of walls or tilting of any structural members, deflections, staining, water leakage, spalling, and corrosion.

- Collect the samples from the site.

STEP 3: Understand the Cracks And Its Causes

Find the type of crack – Is it live or dead crack.

Is it permeability of concrete, corrosion of reinforcement, moisture variation, temperature variation, poor construction practices, poor structural design and specifications, elastic deformation, creep, chemical reaction, foundation movement & settlement of soil, growth of vegetation, additional alternation of structures?

STEP 4: Monitoring And Measuring The Movements Of Cracks

- Using tell-tale

- Crack width gauge

- Precision callipers

STEP 5: Finding The Suitable techniques To Repair Cracks

- Epoxy injection

- Routing and sealing

- Stitching

- Drilling and plugging

- Gravity filling

- Drying packing

- Polymer impregnation and underpinning

STEP 6: Formation Of Report