The sludge that settled after sewage was stirred up freely in the presence of plenty of air oxygen is known as activated sludge. When combined with raw sewage that includes enough oxygen, activated sludge serves as a fertilising ingredient (agent). This is because it contains a lot of aerobic bacteria and other organisms.

1. Organic substances are oxidised.

2. Encourages coagulation and flocculation while transforming dissolved and colloidal materials into settle able solids.

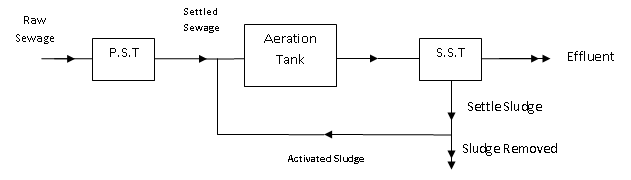

The flow diagram of activated sludge process is shown in the figure below:

The necessary quantity of activated sludge from S.S.T. is combined with the settled sewage from P.S.T. Mixed Liquor Suspended Solid (MLSS) is the name given to the resulting mixture.

MLSS is put through an aeration tank and mixed with air there for 4 to 8 hours. Bacteria oxidise the sewage in the presence of oxygen, reducing the sewage’s BOD. After being aerated, the MLSS is transported to S.S.T. where it can settle. After treatment, the settled sludge is disposed of and some of it is recalculated as activated sludge after the effluent is discharged.

The S.S.T’s effluent is crystal clear water with a very minimal quantity of organic debris, and it may be disposed of without further treatment other than the sporadically used chlorination.

Benefits of the Activated Sludge Process include

- Low installation costs

- Good effluent

- Requires little land.

- Head loss is minimal

- Elimination of odour and insect annoyance good standard of care

Activated sludge process drawbacks

- Not very flexible method (If there is a rapid increase in sewage volume or if there is a quick change in sewage character, there are negative effects on the process’s operation and as a result, poor-quality effluent is produced).

- High operational costs

- Large-scale sludge disposal is necessary

- This method is delicate to some industrial wastes. 5. To ensure that the returned sludge is still active, skilled observation is necessary.