This is a laboratory test that determines the quality of concrete in terms of uniformity, cohesion, and segregation resistance. A normal mass of concrete is jolted in this experiment. The concrete spread or flow is monitored, and this flow is linked to workability.

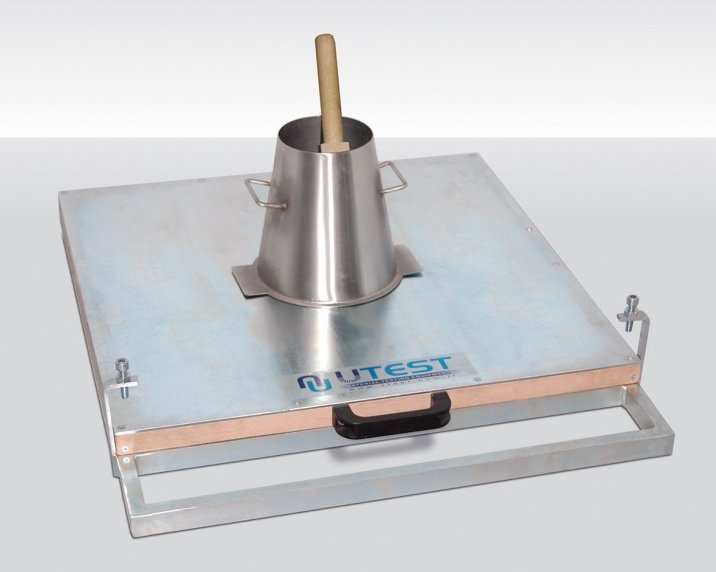

The equipment is made up of a flow table with a diameter of roughly 76 cm and concentric circles marked on it. The following internal dimensions are employed in a smooth metal casting mould in the shape of a frustum of a cone. The base measures 25 cm in diameter, the upper surface measures 17 cm in diameter, and the cone stands 12 cm tall.

The table’s centre is firmly secured and filled in two levels. Each layer is tamped 25 times with a 1.6 cm diameter tamping rod that is 61 cm long and rounded at the lower tamping end. top layer is equally rodded, and the excess concrete that has overflowed the mould is removed. The concrete is pulled vertically upward from the mould and stands on its own. In around 15 seconds, the table is raised and dropped 12.5 mm 15 times. The spread concrete’s diameter is measured to the nearest 5 mm in six directions. It is indicated the average spread.

Consistometer Test using Vee Bee

This is a good laboratory test for determining the workability of concrete indirectly. A vibrating table, a metal pot, a sheet metal cone, and a standard iron rod are used in this test.

The slump test is carried out as described above, with the slump cone being placed inside the sheet metal cylindrical pot of the consistometer. The swivel arm’s glass disc is spun and positioned on top of the concrete in the pot. The electrical vibrator is then turned on, and a stopwatch is started at the same time.

The vibration continues until the conical shape of the concrete vanishes and the concrete takes on a cylindrical shape. This can be determined by looking at the transparency of the glass disc from the top.

The stop watch is turned off as soon as the concrete has entirely assumed a cylindrical shape.

Vee Bee Degree is the amount of time it takes for the shape of concrete to change from slump cone to cylindrical in seconds.

This method is very suitable for very dry concrete whose slump value cannot be measured by Slump Test, but the vibration is too vigorous for concrete with a slump greater than about 50 mm.