Sewer joints can be of the following types:

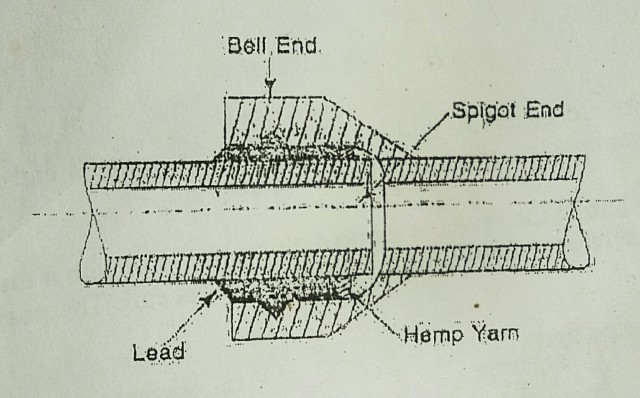

1. Bell and spigot joint:

For stoneware pipes, each connection must be caulked with tarred gasket that is one length for each joint and long enough to completely round the pipe’s spigot end. The seal

shall then be partially dried, filled with a 1:2 cement sand mortar, and a fillet shall be applied made a 45° angle with the pipe’s barrel around the seam using a trowel per IS 4217. For jointing, rubber gasket can also be employed.

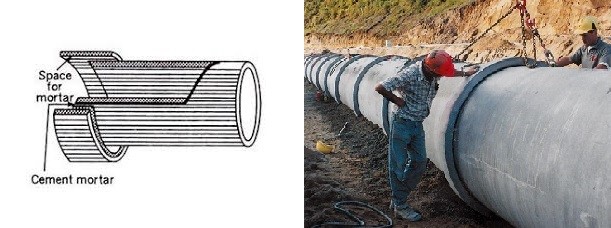

2. Collar joints

The plain ends of the following pipe lengths are kept close to one another for this type of junction, and a collar with a slightly larger diameter is positioned all around it. Then, a 1:1 amount of cement mortar is added to the annular space between the collar and the pipe ends. Larger diameter concrete pipes are used with these joints.

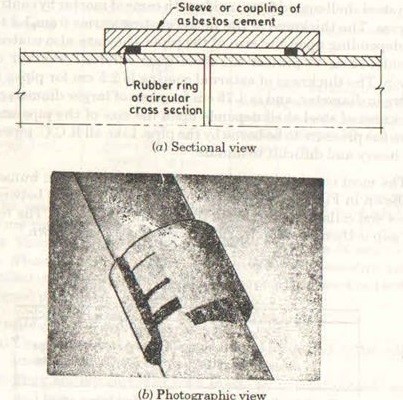

3. Simplex joint.

Similar to collar joints, simplex joints, also known as ring tie coupling, are used for asbestos cement pipes. The joint is made up of two rubber rings that are compressed between the interior of the sleeve and the interior of the pipes, as well as a pip sleeve or coupling made of asbestos cement. Such a joint is very adaptable.

4. Flexible or bituminous joint.

The collar joint using cement mortars is relatively rigid. Such joints crack. These joints are made flexible by using bitumen or bituminous compounds instead of cement mortar.

5. Joints in machines.

To hold the two ends of these joints together, mechanical devices such flanged rings, bolts, screwed ends, etc. are used. Cast iron, steel, and other metallic sewers are utilised with them.

6. Open joint

Unclosed joints Open joints are used if there is no objection to infiltration. Without adding any filler to the annular area, the bell and spigot ends are simply joined. To preserve alignment, a gasket can be placed. To stop soil from entering the sewer, the joint is simply coated with tar paper.