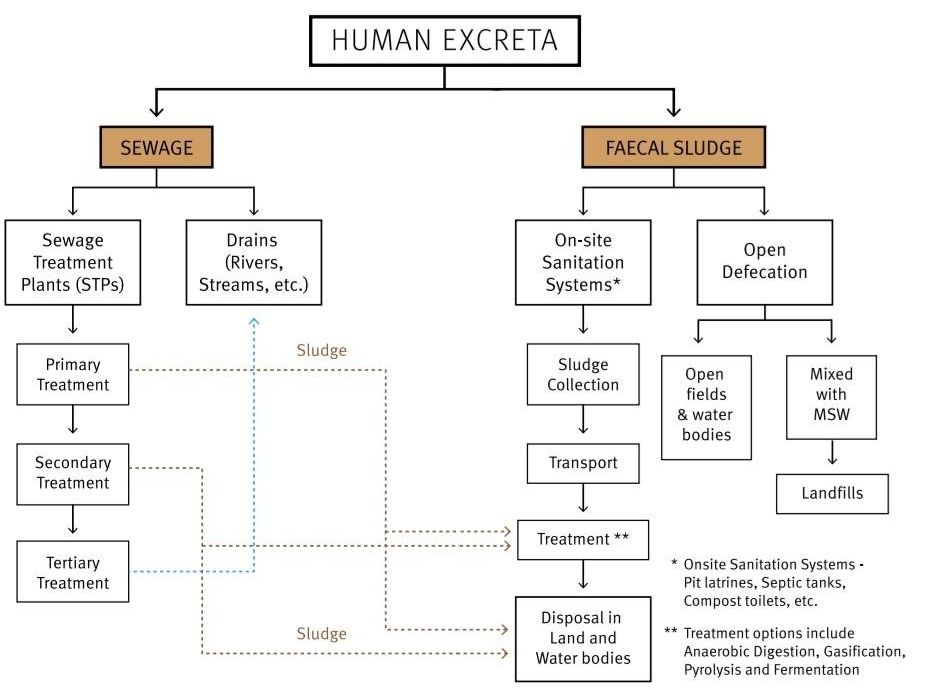

Excreta are a normal part of life. The downside to all of this excrement is that if it is not properly managed, it can lead to waterborne infections and pollution. In addition, a shortage of clean, functional toilets jeopardises human dignity. However, 2.4 billion people around the world do not have access to sufficient sanitation. The 2.7 billion individuals who employ onsite sanitation technologies will play a critical role in resolving the global sanitation crisis. Excreta and wastewater that collect in onsite-sanitation systems are referred to as faecal sludge. It must be safely contained on site, and the collected faecal sludge must be safely emptied, transferred to a treatment plant, processed, and either reused or disposed of. However, Most faecal sludge, on the other hand, is poorly managed, with insufficient and safe emptying, no treatment plants, and unlawful dumping straight into the environment. A substantial number of plant nutrients can be found in faecal sludge (FS). In numerous places, FS (treated/untreated) has been employed as a soil ameliorant. Many different ratios of SW were included into the sludge brick (SB) combinations. Fineness, specific gravity, water absorption, and compressive strength tests were all performed. As a result, a brick with 20% SW utilisation is adequate for producing good quality brick. This research reveals that human faeces can be used as a good material for making bricks with a proportionate mix and design.

1. INTRODUCTION

To treat toilet effluent, most cities in underdeveloped nations in Asia and Africa still use onsite sanitation systems such as septic tanks. The highly polluted septic tank sludge, also known as faecal sludge (FS), must be extracted on a regular basis for treatment and disposal. Fecal sludge management (FSM) has been shown to be inadequate in some places due to a lack of capital, proper technologies, and management policies, resulting in environmental degradation and health issues. The goal of this study was to assess existing FEM practises, as well as their strengths and weaknesses, and to establish FSM indicators for FEM procedures, including collection efficiency, treatment efficiency, benefit/case ratio, and societal satisfaction. Factors influencing the efficiency of the FSM indicators were found and simulated using data obtained from 50 cities. An FSM effectiveness diagram was created and evaluated using real data from four Asian cities with varying FSM efficiency. The findings highlighted the contributing elements affecting these cities’ FSM efficiencies and suggested practical solutions for enhancing FSM procedures. The proposed effective FSM measures are recommended for application by various localities in order to reduce envy.

The collection, transport, and treatment of faecal sludge from pit latrines, septic tanks, or other onsite sanitation systems is referred to as faecal sludge management (FSM). Fecal sludge is a mixture of human excrement, water, and solid wastes that is disposed of in onsite sanitation systems’ pits, tanks, or vaults. Septage is faecal sludge that is cleaned from septic tanks.

Bricks have been created out of clay for thousands of years. The sludge from the (WTP) is almost identical to the clay in bricks. It also has a similar chemical make-up. As a result, this sludge can be utilised as an effective clay brick substitute. It is primarily Concentrations, bioavailability, and chemistry such as Cu, Cr, Zn, Cd, and Pb in tannery waste sludge were studied, as well as the effects of heavy metals in brick on affecting chemical-physical properties. The natural resource is practically employed for the construction of sludge bricks as an alternative to traditional cement bricks, which aids in resource conservation and improves environmental quality.

2. PURPOSES

FSM concerns are becoming more popular and well-known over the world, especially in Africa and Asia. Large-scale research and development programmes in the FSM domain attest to this. A variety of organisations are conducting and funding such research.

Faecal sludge is not managed correctly in many impoverished countries. This could be due to a lack of mandatory institutions, a lack of technical skills and experience, an inability to get finances for vacuum trucks and treatment, and a lack of understanding required to launch and implement successful FSM programmes. This can lead to the septic tank and pit latrine overflows, as well as poor performance of onsite sanitation facilities (OSSFs). This can lead to poor onsite sanitation facility (OSSF) performance, septic tank and pit latrine overflows, unsafe pit latrine emptying, and the discharge of untreated pathogenic faecal sludge into the environment.

FSM programmes are among them, and they are designed to:

- Minimize odours and nuisances, as well as the uncontrolled discharge of organic matter from overflowing tanks or pits.

- Improve the operation of onsite sanitation systems and limit the possibility of human contact with faecal-borne infections.

- Protect public health against indiscriminate disposal of collected faecal sludge

- Derive agricultural products, such as soil conditioner from composting or co-composting materials, and energy products, such as biogas, charcoal pellets, industrial powdered fuel, and so on, from composting or co-composting materials.

- Promote economic development, job creation, and livelihood options for informal workers while addressing issues such as social stigma and operator health and safety.

In a variety of ways, FSM programmes can contribute to better sanitation. They can incentivize OSSF modifications that reduce (or increase) desludging frequency and, as a result, operational and environmental expenses. They have the potential to be economic catalysts as well.The sanitation value chain is undergoing development. This could include supplies and parts for new toilets and septic tanks.Contractors and equipment installers, sludge collecting employees such as drivers and emptiers, and treatment and reuse system operators are among the positions that may be available. It can also comprise the manufacturing and marketing of sludge treatment process end-products. Recycled water for agriculture and industry, soil conditioners, biogas, biodiesel, and power are just a few examples of these products.

The Problem With Biosolids

‘Sewage sludge’ is another name for biosolids. It’s the sludge that comes from the sewage, to put it simply. Sewage sludge becomes biosolids, which are organic compounds rich in nutrients produced by wastewater treatment facilities, after being appropriately treated and refined.

Incoming wastewater streams are controlled and monitored in wastewater treatment plants to ensure their recyclability and compatibility with the treatment process.

Biosolids can also be recycled and used as fertiliser to promote plant development and improve and maintain healthy soils. The EPA goes on to say that proper sewage sludge and biosolids management ensures that valuable materials are recycled on land and potentially harmful materials are not dumped into bodies of water.

Reuse Potential of Faecal Sludge

Human excreta is a good source of organic matter and plant nutrients that can be used as fertiliser and soil amendment in agriculture. The highest concentration of organic matter is found in human excreta, but urine has higher concentrations of nitrogen (70-80 percent) and potassium. However, phosphorus is distributed evenly in urine and faeces (Otterpohl et al., 2003). Excreta, on the other hand, contains a higher concentration of pathogenic bacteria and, as a result, must be thoroughly sanitised before to use (Albihn & Vinners, 2007; Winker et al., 2009). Composting, vermicomposting, shallow trenches, anaerobic digester, solar drying, and other well-known procedures for cleaning and converting organic wastes into valuable output include: composting, vermicomposting, shallow trenches, anaerobic digester, solar drying, and so on.

The following factors may alter the properties of faecal sludge:

- The efficiency of the various types of desludging equipment.

- Seasonality – the existence of groundwater or floodwater that may penetrate into tanks and dilute the contents.

- The last time the tank was dislodged (age of faecal sludge).

Blocks of dried human faeces could be used as building materials for houses of the future.

Sewer sludge is currently being fully treated and dried, while the remaining ‘biosolid’ is being discarded in landfills. A new method for combining clay with faeces to generate a unique type of building material has been created. Bricks using 25% faeces and the rest of traditional clay passed tough strength testing.

They’re also more porous and more effective insulators.

The biosolid material might be mixed with clay and used to make bricks, reducing the 30% of sewage that is still transported to landfills or stored.

‘Using only 15% biosolids in brick production would minimise the carbon footprint of brick production while meeting all environmental and engineering standards for bricks,’ says the study.

The bricks use less energy to manufacture and can withstand even the most stringent building codes.

This reduction in energy consumption is favourable for both the environment and the wallet.

Regular bricks are manufactured in kilns at temperatures above 2,500 degrees Fahrenheit, releasing massive amounts of CO2.

‘Biosolids in bricks could be the answer to these major environmental issues.’

Instead, the new approach produces nitrogen and potassium, which can be used as fertilisers in commercial applications.

Urine is collected in new fertiliser-producing urinals and utilised to generate a solid industrial product, with the residual liquid going into the brick.

Urea in liquid urine is broken down by bacteria in the form of urease, which produces calcium carbonate through a chemical process.

This binds the sand together into the desired shape, which can be a column or a rectangular building brick. The researchers can utilise the same process to make bricks that can be customised to fit the needs of a particular building project. How long bacteria are allowed to grow in the brick-shaped sand mould determines how dense the bricks are.

Traditional clay bricks must be burnt at high temperatures, releasing dangerous carbon dioxide as a byproduct, whereas urine-based “bio-bricks” can be created at room temperature. As a byproduct, they only leave nitrogen and potassium, both of which are great fertilisers. Calcium phosphate, another fertiliser, is made from the urine’s remaining calcium.

3. OBJECTIVES

- Pathogen reduction is a common inactivation goal of faecal sludge treatment to protect public health. Bacteria, viruses, protozoa, and helminths are pathogens that cause disease.

- Dewatering (or “thickening”) of FS is an important treatment goal since FS comprises a high amount of liquid, and reducing this volume reduces the cost of conveying water weight significantly.

- Biodegradation of the more easily degradable compounds achieves stabilisation, resulting in an FS with lower oxygen demand.

- Management

- Nutrients such as nitrogen, potassium, and phosphorus can be found in faecal sludge.

- These nutrients are required for plant growth, and their efficient use simplifies subsequent treatment stages.

- To propose an alternative to traditional brick.

- Create a light-weight brick.

- To achieve sturdiness and viability

- To investigate the impact of dry sludge on bricks.

LITERATURE REVIEWS:

- MILIVOJ PETRIK: Agricultural use of night soil sewage and sewage sludge (In 1954)

- From two perspectives, the author examines the agricultural use of night soil, sewage, and sewage sludge: strictly agricultural and hygienic.

- There is still a lot of work to be done in terms of understanding the chemistry and bacteriology of human faeces, and there is still a lot of work to be done in terms of figuring out how to digest night soil in a short amount of time into a high-fertilizing end product that is free of pathogens, parasites, and weeds.

- EMMANUEL ALEPO ODEY: Fecal Sludge Management in Developing Urban Centers: An Overview of Collection, Treatment, and Composting ( IN 2017 )

- This paper discusses better faecal sludge management and technologies for soil amendment, which are divided into three categories: (1) collection, (2) treatment, and (3) composting.

- The main problems associated with the collection and treatment of faecal sludge, such as inadequate to and improper treatment processes, are summarised based on the literature review, as are the trends and challenges that concern the applicability of each of the technologies in developing urban centres.

- PETER M HAWKINS: A comparative review of 12 cities’ faeces sludge management (In 2014)

- The outcomes of faecal sludge management scoping study in 12 cities are presented in this report.

- Despite differences in performance, none of the cities analysed managed faecal sludge well.

- Where communities are attempting to address faecal sludge issues, the solutions are, at best, piecemeal, with an emphasis on severage that, in most cases, serves a small minority.

- FSM necessitates robust city-level oversight and an enabling environment that promotes coordinated actions throughout the sanitation service chain; this was often lacking in the cities examined.

- MUHAMMAD ASHRAF ALI: Fecal Sludge Management in Urban Ares of Bangladesh(IN 2015)

- Over the last decade, Bangladesh has seen a tremendous increase in on-site sanitation facilities across the country, with the key achievement in urban sanitation being the elimination of open defecation among the poorest quintile through the use of on-site sanitation facilities.

- Usage of Sludge as a Construction Material by J. Balasubramanian a, P.C. Sabumon a, John U. Lazar a, R. Ilangovan

- Content: The compressive strength of 10%, 20%, and 30% sludge is 4 N/mm2,3.74 N/mm2, respectively, and loads were calculated according to IS: 2185(part1) – 1979. As a result, 30 percent replacement is acceptable for non-structural items.

- Mahdi Haroun, Azni Idris 1, and S.R. Syed Omar, “Characterizations and Composting of Tannery Sludge.” Article Content: The characteristics of tannery sludge and their qualities during composting were discussed in this study.

- Leather industry sludge waste produces up to 600 tonnes of sludge, which contains higher inorganic nitrogen (N) organic wastes.

- Oladoja and Bamuza Pemu‘s treatment of textile sludge with an anaerobic technique.

- Content: This paper focuses on the proper treatment of sludge via anaerobic digestion. The sludge was dewatered with a sand bed and disinfected with calcium oxodichloride (CaOCl2) until the residual chlorine level was between 0.2 and 0.7 mg/L. Solid content, BOD and COD values, nitrogen content, phosphorus concentration, and NPK content of raw and treated sludge as a percentage decrease/increase. The amount of phosphorus in the sludge was reduced by roughly 53%, but it was raised by 59.53 percent in the liquid.