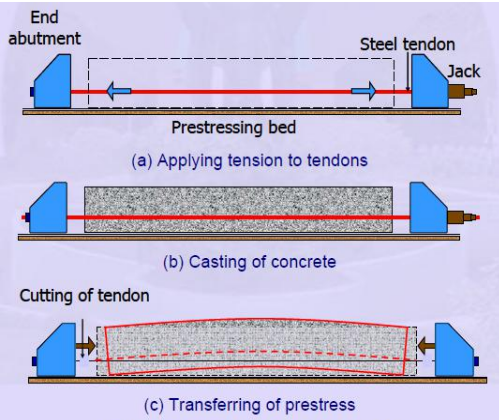

Prior to the casting of concrete, the high-strength steel tendons are pulled between two end abutments (also known as bulkheads) in a pre-tensioning system. The ends of a prestressing bed are where the abutments are fixed. The tendons are cut free from the concrete after it reaches the necessary strength for prestressing are the abutments. Due to their link, the tendons’ prestress is passed from them to the concrete. Elastic shortening occurs on the member during prestress transfer. Should the tendons be the component is prone to flex and deflect if it is eccentrically positioned (camber).

The various stages of the pre-tensioning operation are summarised as follows.

- Anchoring of tendons against the end abutments

- Placing of jacks

- Applying tension to the tendons

- Casting of concrete

- Cutting of the tendons.

During the cutting of the tendons, the prestress is transferred to the concrete with elastic shortening and camber of the member.

Advantages of Pre-tensioning:

The relative advantages of pre-tensioning as compared to post-tensioning are as follows.

- Pre-tensioning is suitable for precast members produced in bulk.

- Prestressed concrete structure Dr.Amlan K and prof.Devdas Menon

- In pre-tensioning large anchorage device is not present.

Negative effects of pre-tensioning:

The following are the relative drawbacks.

- The pre-tensioning process needs a prestressing bed.

- Before the concrete reaches a sufficient strength, it must wait in the prestressing bed.

- Over the transmission length, concrete and steel should be well-bonded.

Devices:

The essential devices for pre-tensioning are as follows.

- Prestressing bed

- End abutments

- Shuttering / mould

- Jack

- Anchoring device